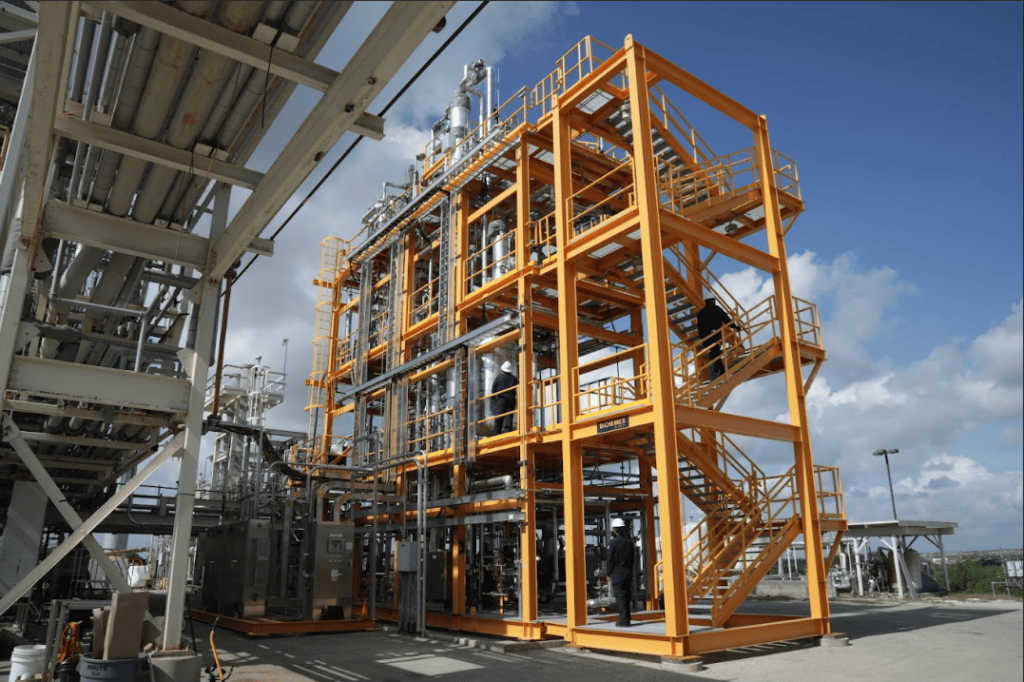

Circular Chemicals Facility

Client: Encina Development Group

Location: San Antonio, Texas, USA

Scope: Turnkey

Shaw Projects & Modules completed engineering, procurement, fabrication, and installation scope for a cutting-edge 960-ton-per-day circular chemicals facility in San Antonio, Texas. Completed in just eight months in 2023 on a fixed price basis, this project highlights Shaw’s expertise in delivering complex modular solutions on time and within budget.

This facility was designed to convert mixed end-of-life plastics into valuable circular chemicals using proprietary recycling technology. This process operates at the molecular level, breaking polymer chains into their original monomers, such as benzene, toluene, xylene (BTX), and propylene. The recovered monomers are then used to produce new plastic products, contributing to a sustainable, circular economy.

Shaw Projects & Modules’ scope involved deep process engineering, particularly scaling the design from bench scale to demonstration scale. The facility also required expertise in high-temperature applications at low flow rates which posed a unique project challenge. This project won several national-level awards for both execution and safety performance.

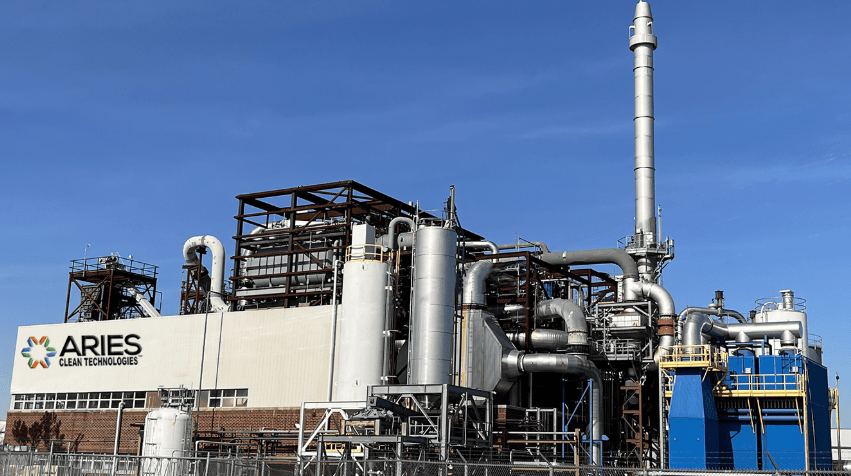

Municipal Solid Waste Gasification Facility

Client: Aries Clean Technologies

Location: Linden, New Jersey, USA

Scope: Turnkey

Shaw Projects & Modules completed engineering, procurement, and installation scope on a revamp/debottleneck of the world’s largest Municipal Solid Waste (MSW) Gasification Facility in Linden, New Jersey. This landmark facility, completed in 2023, is designed to process 430 tons of biosolids waste from municipal wastewater treatment plants per day using a proprietary fluidized bed gasification system.

The facility offers a more sustainable and efficient alternative to traditional wastewater treatment effluent management methods, such as landfills and land application. Its advanced gasification technology converts biosolids into clean thermal energy, delivering an environmentally friendly waste management and resource recovery solution.

Shaw P&M’s contributions showcase its expertise in developing innovative, scalable solutions that drive sustainability and operational efficiency.

Advanced Plastics Recycling Facility

Client: Freepoint Ecosystems

Location: Hebron, Ohio, USA

Scope: Turnkey

Shaw Projects & Modules delivered engineering, procurement, fabrication, installation, and commissioning scope under a financeable, lump-sum turnkey contract for a groundbreaking 240-metric-ton-per-day Advanced Plastics Recycling Facility in Hebron, Ohio. Scheduled for completion in late 2024, this state-of-the-art facility represents a significant step forward in sustainable waste management and is believed to be the largest such operational facility in North America.

The facility employs innovative advanced recycling technology, utilizing proven pyrolysis processes to convert waste plastics into valuable resources while significantly reducing the volume of plastics sent to landfills. All modules were expertly fabricated at Shaw’s state-of-the-art module facility in Lake Charles, Louisiana, and transported to the project site as truckable modules, ensuring efficiency and quality. This project also required advanced material handling expertise, highlighting Shaw’s leadership in procurement and fabrication capabilities.